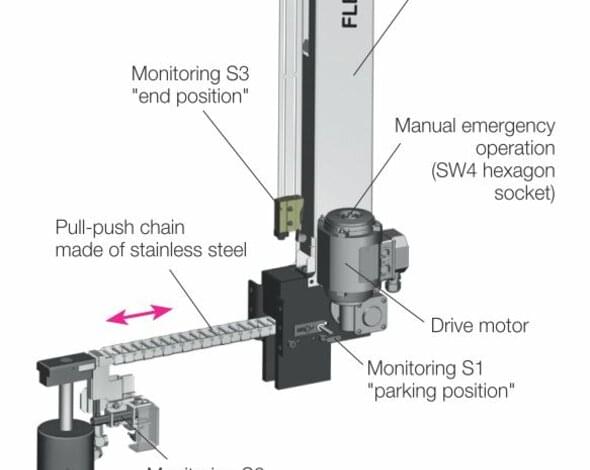

With two innovations ROEMHELD provides increased availability and easier maintenance of its rotor lock rotor lock for wind turbines: A non-contact position control avoids mechanical.

A contactless position control avoids mechanical wear and thus extends the service life, and a new special coating prevents the locking bolt from rusting during longer standstills. The two special solutions originally developed for customer projects are now offered by ROEMHELD as quickly available standard components.

With the help of a new process the permanent corrosion-free coating of the bushing, in which the locking bolt is stored during the operation of the wind turbine, succeeds. This prevents rusting between maintenance intervals and eliminates the need for regular greasing, as is the case with other models. The rotor lock is permanently ready for use and also reduces the effort required for turbine maintenance. The surface protection of all rotor lock components complies with DIN ISO 12944, C4, so that they can also be used in offshore operation.

The second innovation in position control is also aimed at longer service life and high availability. A contactless switch determines whether the pin is in the park position or locks the rotor. Since there are no mechanical contacts that can wear out, replacement is also not necessary.

ROEMHELD manufactures the rotor lock, which can be moved hydraulically or electromechanically, according to customer specifications and supplies customers all over the world. The rotor lock can withstand transverse forces of up to 7,000 kN and is used for locking the rotors of onshore and offshore wind turbines with an output of up to 6.5 megawatts. With its compact design, the locking module is adapted to the confined space conditions in the nacelle. The use of standardized components makes it possible to manufacture even complex special designs quickly and cost-effectively.

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.