Besides wide-ranging solutions for workpiece and tool clamping technology, ROEMHELD is also dedicated to the requirements of the wind power industry.

For the safe maintenance and locking of wind turbines, both on- and off-shore, the ROEMHELD Group develops and manufactures at the location Hilchenbach, besides customized solutions for rotor locking, also clamping elements for the rotor blade production - everything of course completely "Made in Germany".

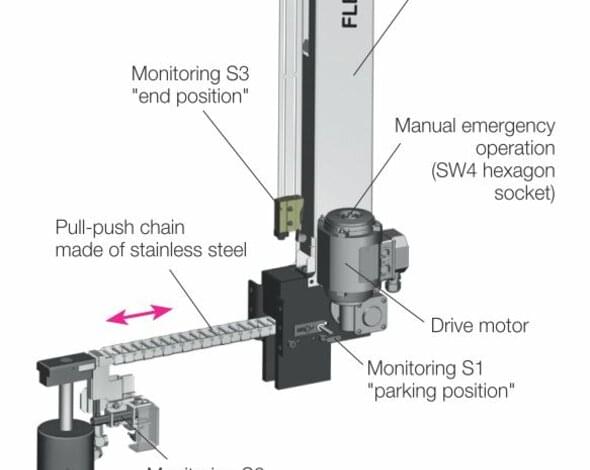

The rotor interlocks for inspection and maintenance tasks consist of standard modules that are configured according to a consistent concept: This means that even complex special designs can be supplied quickly and cost-effectively. The elements are based on a hydraulically or electromechanically moved, double-acting bolt with position monitoring, which reliably locks the rotor with forces of up to 4,900 kN. Options such as adjustable position monitoring or additional mechanical locking are available.

The locking devices are designed for use at temperatures between -30° C and +70° C and are maintenance-free. Adapted to the confined space conditions in the nacelle, they have an extremely compact design. All rotor locks are manufactured by the ROEMHELD Group according to customer-specific requirements in Germany and delivered to customers worldwide.

The locking systems are available either as onshore or offshore version, both with a special surface coating according to the requirements of DIN EN ISO 12944. Due to a special corrosion-resistant coating, safety and reliability can be guaranteed over long periods of time: ROEMHELD is oriented towards the average operating time of offshore plants of about twenty years or the special different customer requirements.

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.