Die changing cart RW 500 / RWA 500

without and with integrated auxiliary drive

with safety docking station

max. load capacity 500 kg

manually movable, without and with integrated auxiliary drive, with safety docking station, max. load capacity 500 kg

Application

Die changing carts RW / RWA 500 facilitate the handling of medium-weight dies and enable dies weighing up to 500 kg to be safely transported in a way that saves effort and time.

Die changing cart RW 500 is moved manually; the RWA 500 versions also have a battery-powered auxiliary drive.

All cart types are specifically designed for pressing and punching dies as well as for injection and casting moulds.

Description

Die changing cart RW 500 is moved manually; for added convenience, the RWA 500 version is equipped with a battery-powered auxiliary drive for easier transportation.

The changing table is equipped with ball inserts that make it easier to insert the dies manually.

The height of the table can be adjusted via a hydraulic lifting column using a foot pedal.

Die Changing Carts RWA 500 with auxiliary drive

All elements of the auxiliary drive are integrated in the front axle: the electric motor including gear, long-life batteries with high energy density and a power control for optimum control of the motor.

An integrated level compensation ensures an optimum contact pressure of the drive wheel on the hall floor.

A cover protects the drive against jolts and splash water. The high drive torque of the electric motor (17 Nm / 20 daN) facilitates considerably the movement of the changing cart.

The ergonomic handle consists of two solid handles; speed and direction of the drive can be controlled by means of a rotary toggle on the right handle.

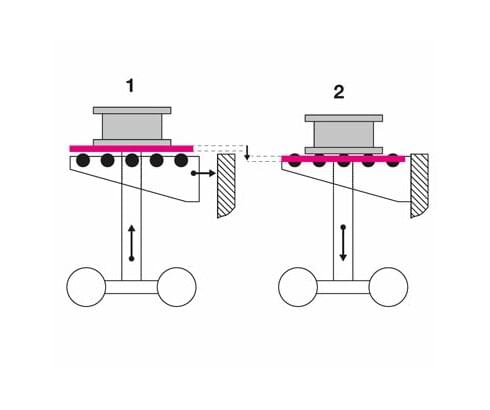

Safety docking station

The docking hooks (2 pieces included in our delivery) for mounting on the changing or press bed (accessory) ensure precise locking of the die changing cart. Ball inserts are lifted by successful docking to the press bed. The die weight is supported entirely at the press bed.

1. Transport

- lifting column extended

- ball inserts lowered

- die on table plate

2. Docking

- lifting column lowered

- ball inserts lifted

- die on ball inserts

| Item no. | CAD data | stroke [mm] | series | max. load capacity [kg] | drive | |

|---|---|---|---|---|---|---|

|

Item no.

|

CAD data

|

Properties

| ||||

|

Item no.

|

Properties

| |||||

|

Item no.

|

CAD data

|

Properties

| ||||

|

Item no.

|

CAD data

|

Properties

| ||||

|

Item no.

|

Properties

| |||||

|

Item no.

|

CAD data

|

Properties

| ||||

|

Item no.

|

CAD data

|

Properties

| ||||

|

Item no.

|

Properties

| |||||

|

Item no.

|

CAD data

|

Properties

| ||||

|

Item no.

|

CAD data

|

Properties

|

| Item no. | CAD data | Description |

|---|---|---|

|

Item no.

|

CAD data

|

Description

Docking hooks (1 set = 2 pcs.)

as per catalogue sheet WZ 8.8900

|

|

Item no.

|

Description

Battery charger

Type S = Standard 1.8 A

100 … 230 V AC, 50 / 60 Hz

Charging time 3 h (approx. 90 %)

as per catalogue sheet WZ 8.8900

|

|

|

Item no.

|

Description

Battery charger

Type Q = Quick battery charger 4.0 A

100 … 230 V AC, 50 / 60 Hz

Charging time 1.5 h (approx. 90 %)

as per catalogue sheet WZ 8.8900

|

|

|

Item no.

|

Description

Battery charger

Type S_US = US version 1.8 A

120 V / 60 Hz alternating current

as per catalogue sheet WZ 8.8900

|

|

|

Item no.

|

Description

Adaptor plate with docking hooks

as per catalogue sheet WZ 8.8900

|

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.