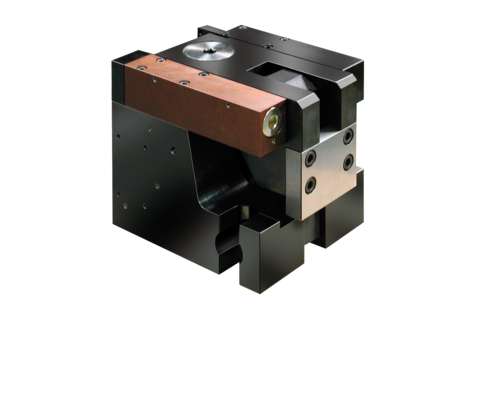

Extending Clamps

double acting, max. operating pressure 100 bar

with mechanical lock, double acting, max. operating pressure 100 bar

Clamping

First, the cylinder piston pushes the clamping lever into the clamping position to the die clamping edge. Released by the hydraulic sequence control, pressure is then applied to the clamping and locking mechanism. Once the clamping force is built up, the clamping element is self-locking. This mechanical lock prevents unintentional unclamping of the die even if there is a pressure loss.

Unclamping

For unclamping, the clamping and locking mechanism is hydraulically unlocked.

Released by the hydraulic sequence control, pressure is applied to the cylinder piston which pushes the clamping lever into the unclamping position. Unclamping and clamping positions are monitored by inductive proximity switches.

Special features

- compact housing and high force density

- high operational safety by position monitoring and automatic motion sequence

- self-locking by mechanical lock

- low operating pressure 100 bar

- easy installation

Special versions on request

- design and position of plug-in connection for proximity switches

- proximity switches for temperatures up to 120°C

- cover plate for better protection in extremely dirty environments

- clamping edge height larger than 60 mm

| Item no. | CAD data | type | functioning | max. operating pressure [bar] | hydraulic ports | |

|---|---|---|---|---|---|---|

|

Item no.

|

CAD data

|

Properties

| ||||

|

Item no.

|

CAD data

|

Properties

| ||||

|

Item no.

|

CAD data

|

Properties

| ||||

|

Item no.

|

CAD data

|

Properties

|

with 4 block clamps 2.2480

Block clamp 2.2480

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.