Grip Rail Couplings

hydraulic, mechanical, electro- and hydro-mechanical version

Applications

- Automatic centring, coupling and clamping of grip rails on transfer presses

- The coupling is used whenever the maximum clamping force with high dynamic strength in the smallest space is required

Description

In contrast to conventional systems, the new coupling design is such that all components for positioning, centring, clamping force build-up and position monitoring are integrated into the active part of the coupling which is firmly connected to the press. The passive part of the grip rail coupling does not have any moving parts. In order to keep the weight of the coupling low, the housings of both the active and the passive parts are made from hard-coated, high-strength aluminium.

When moving the two halves of the coupling into position (insertion of grip rail), these are pre-centred by guide elements. During clamping, positioning pins on the active part extend and locate in bore holes in the passive part. By means of this type of centring a high repeatability is obtained. The clamping force is built up using a tie rod and maintained in a self-locking manner. A compact position monitoring system installed in the element is easily adaptable to a bus system and this ensures exact positioning and clamping.

As an option, rapid action couplings for energy, compressed air and hydraulic oil can be designed as per customer's specification.

Special features

- safe coupling and uncoupling in a few seconds

- die positions are quickly and accurately reproducible

- high positioning accuracy of ± 0.02 millimeter

- easy retrofit

- no movable parts in the passive part of the coupling, thus maintenance-free and affordable

- self-locking

- high dynamic rigidity

- flexible design of the energy couplings as per customer's specification

After applying hydraulic pressure, the coupling halves are centred, clamping force is built up and the tie rod is mechanically locked. Even in the event of a pressure drop the

clamping force is fully maintained by mechanical self-locking. For safety reasons, we recommend that the hydraulic pressure is maintained.

By turning the hexagon socket the positioning pins are extended using a wedge system for centring the coupling halves, and the clamping force is built up. The self-locking wedge system, the high clamping forces and the high dynamic strength are the outstanding features of this clamping element.

The rotary movement of the drive motor is transmitted to the tie rod and the positioning pins using a flex-spline gear and a spindle drive. The operating principle and the arrangement of the gear, position monitoring and automatic sequence of movement ensure high operational reliability.

By turning the hexagon socket the integral hydraulic pad is preloaded and transforms a low torque into a high clamping force.

An indicator pin indicates that the clamping force has been reached.

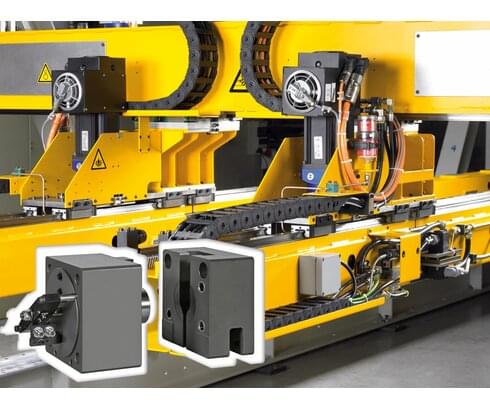

3-axis transfer system with hydraulic grip rail coupling (transfer rail coupling)

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.